Now I came to the climax of the whole job - the fitting of the main action relay and keyframe, connected with new plastic tubing. These constitute the organ's nerve-centre, and had been very meticulously restored in my home workshop, storing them in the organ lorry when done, in readiness for installation.

The relay comprises three main parts: primary puff-board, relay, and main puff-board. The keyframe outlets connect to the primary puffs, and the secondary puffs operate the stickers on the main chest. The whole assembly was made in two sections for ease of handling.

The two puff-boards were simply cleaned and re-leathered. New card discs were applied to the puffs, with those of the main board being smaller than before. This was to ease the flexibility of the puffs in operation. The relay itself had presented some unusual problems. Firstly, all its main assembly screws had been tightened down so many times that their countersunk heads were around 10mm deeper than they should be, with the tips of the screws beginning to pierce the puff spaces below. A simple solution would have been to fit cup washers, but, more authentically, I plugged all these holes and started again.

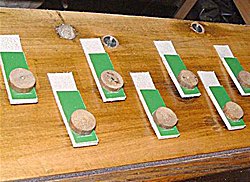

Now the main problem was with the holes in the top board carrying the stickers for opening the internal pallets. Over the years the timber had moved to the extent that these holes were no longer vertical. They leaned at up to 3 degrees, as seen in this picture. Consequently the external valves no longer adequately sealed off the disc exhaust valves. A solution had to be found, short of replacing the top board altogether.

I decided to replace the exhaust valves with flat pallets. These had to be low-profile to avoid the puff-board being mounted too high, so a new material was used. "Foamex" is a light-weight plastic foam with hard surfaces, and available in sheets of various thicknesses. I chose 1.5mm. The pallets were leathered in the traditional way, and mounted in position with leather hinges at the back. Small wooden discs were glued to the pallets to be pressed down by the puffs above. Of course, this modification is completely reversible, and in no way compromises the true nature of the restoration. As with all the other action parts, all springs were renewed in phosphor bronze.

The two relay sections were positioned over the main chest's stickers and screwed down. A small amount of adjustment was necessary in height, but the job had been made far easier than previously by carefully setting the sticker lengths in advance. Once the four wind-trunk links were fitted - new Kopex was used as the previous set had begun to disintegrate - the action was tested on the wind. It would have been useless to merely blow by mouth into the relay inlet tubes as it needed the correct pressure, so I set-up a tube fitted into the hole reserved for the keyframe shut-off, not yet installed. Testing went completely without a hitch, mostly due to the relay having been tested and adjusted at home.

| Pages: 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 |

© 2018, John Page